MATERIALS

SOLID PRODUCTS REQUIRE THE BEST MATERIALS

DISCOVER THE BEST MATERIALS FOR YOUR INVESTMENT

Luxum® has the knowledge and advanced technology to offer. We are able to cope with virtually any, even the most complex projects in the field of interior design. We reliably realize the most beautiful projects of the 21st century using traditional materials that are closest to nature. Thanks to the use of such materials we can live in harmony with the surrounding nature. For those who want a change, something new or unusual, Luxum® prepares equipment that sets new trends, using ultra-modern, innovative and world-leading composite materials. It is thanks to these materials that unprecedented designs and timeless interiors are created.

Below you will find more details about the selected materials, with the help of which Luxum – you will realize what you want! We are talking about composites and conglomerates for the production of exclusive equipment with GFK Luxum®, Cristalstone® and Solid Surface: Corian*, Hi-Macs, Kerrock, Staron. An interesting solution is also the innovative architectural concrete Luxum® in Creative-Concrete® panels, for decorating walls, facades, floors, fences and fireplaces, and waterproof polymer architectural concrete for casting worktops and sanitary equipment such as washbasins, bathtubs and shower trays.

Perhaps an intriguing material for architects and fans of hi-tech technology is carbon fibre, which Luxum® was the first to introduce to the Polish market for the production of interior design, small architecture and sanitary equipment. Until now, we are the only Polish company that has the technology of processing and forming carbon fiber for the production of interior design elements and bathrooms.

CORIAN® and other Solid Surface composites

Staron®, Hi-Macs®, Kerrock®, Montelli®, Krion®, Hanex®

DuPont’s invention of Corian® was the first Solid Surface material on the market. Later, with the development of the interior design market with extraordinary possibilities, other brands such as Staron, Kerrock, Rausolid, Hi-Macs, Hanex, Montelli, AB-Laminati joined the market. Solid Surface are mineral-acrylic panels made of mineral filler and polymethyl methacrylate (PMMA), i.e. acrylic resin. Corian® and other solid surfaces are used in the private, commercial and public sectors. Among others, in hotels (e.g. Corian receptions are made), shopping malls, ports, on ships or in health care. These are solid surfaces that offer extraordinary design possibilities and will serve their users for many years to come. Balancing beauty and durability, Solid Surface composite material is ideal for innovative and sophisticated architectural creations. Among others: composite worktops, various forms of furniture and sanitary products, especially washbasins, bathtubs, shower trays and applications to be used for many years.

Corian® from DuPont is a Solid Surface composite that has been the market leader so far. Corian® washbasins impress with their beauty and performance. Tops made of this material are a prestige in a true European style. Thanks to its unique properties, Corian® tops, like those made of Staron, can be bent and moulded in 3D during the manufacturing process, which results in the most creative stone forms. Wash basins, countertops, furniture and other Corian® products can be easily renovated, making them always look like new! It is from Corian® that we produce unique washbasins for the best Western brands.

Corian® and other similar solid surface composites are used to make the most exclusive sanitary equipment by the world’s best companies. At Luxum® we create solid surface sanitary equipment from composites – bathtubs, washbasins, shower trays, countertops, built-in and furniture.

WHATEVER YOU IMAGINE, THERE IS A GREAT CHANCE THAT LUXUM WILL BE ABLE TO CREATE IT FOR YOU WITH A SOLID SURFACE MATERIAL.

Solid Surface composite can be:

cut and cut

carved and processed like wood

ground

thermally formed

combined with other materials

The possibilities of designing and creating with the use of composites are practically unlimited. Homogeneous Solid Surface composites with no visible joints are available in Luxum® in more than 500 smooth, marbled and other natural, modified, fancy and metallic colours. They can also be used to create large architectural objects. Corian®, Staron®, Krion®, Rausolid®, Kerrock®, Hi-Macs® also combine very well with other materials such as tiles and terracotta, stainless steel as well as architectural concrete, wood, granite and glass. They are suitable for both vertical and horizontal applications.

They allow you to create unique furniture, sanitary products, small architecture and lighting objects. The list of possible applications is constantly growing and evolving.

The solid surface material Staron® from Samsung, the equivalent of Corian®, is a high quality Solid Surface composite, also known as “synthetic stone”. Staron® custom washbasins are characterized by excellent aesthetics and interesting colors. Staron® is appreciated for its extraordinary durability and wide choice of colours. What’s more, Staron® wash basins and worktops can be restored to their original beauty after a long period of use.

One of the most popular solid surface composites is Krion® by the Spanish company Porcelanosa. It is one of the youngest representatives of the luxury solid surface materials. Porcelanosa’s reputation and experience in the production of exclusive sanitary equipment have resulted in the delivery of solid surface composite material of excellent quality and a very interesting colour design. Currently Krion®, thanks to a slightly lower price such as Corian® and an interesting, modern range of colours, is gaining popularity and is willingly chosen by investors, architects and interior designers.

The above mentioned other solid surface composites, such as Kerrock®, AB Laminati®, Hi-Macs®, Montelli®, Rausolid®, Acrea®, etc., have practically identical properties to those of Krion®, Corian and Staron®.

In the Luxum® Creative Interiors Gallery in Krakow, there are examples of products and arrangements made of solid surface available. You can also see samples of all the above mentioned solid surface composites on site.

GFK Luxum® – an innovative lightweight, high-quality composite.

GFK Luxum® is one of the greatest technological advances in the field of composite materials in the sanitary and interior design sector. This lightweight material is exclusively produced by the Luxum® brand. It is a modern composite material that combines exceptional lightness and strength. The lightweight composite GFK Luxum® is a synergy of modern craftsmanship with innovative moulding and casting technologies. It allows you to produce exclusive equipment of the highest aesthetic and functional value, even in individual, unique pieces, which are made to measure, to individual order.

The material is even ideal for the production of large-size, free-standing, untypical bathtubs, also with a linear overflow and equipped with customized hydromassage systems. Thanks to the unique properties of GFK Luxum®, it is possible to create untypical, long, unlimited in form bathroom sinks, also double and multi-station ones. It is the only material that allows to produce large and long hanging washbasins as self-supporting products without additional substructure. What is important, such washbasins with worktops can be mostly mounted on light walls. GFK Luxum® also creates shower trays, shower surfaces and unique architectural solutions and bathroom countertops.

The equipment made of GFK Luxum® is significantly lighter than its equivalents made of ordinary, popular materials, such as cast marble (artificial stone), ceramics, ceramic derivatives under various trade names and even a solid surface. At the same time, they noticeably outperform the competition with durability and comfort of use. The composite is warm and pleasant to the touch. Perfectly smooth and easy to keep clean. It helps to maintain a high level of hygiene without any effort. The secret of the material is an internal structure made of glass fibre, a noble filling and a hard, outer layer of gelcoat. Unlike many competing materials, GRP Luxum® is UV-resistant and does not yellow even after many years of use. The surface of GRP Luxum® products can be repaired and regenerated, so that the products can actually last forever. An important aspect when choosing GRP Luxum® is its thermal insulation properties. Bathtubs made of this composite maintain the temperature of the water for a long time.

Sanitary products, bathroom countertops, furniture countertops, reception counters and small architecture products with GFK Luxum® are the most exclusive products, characterized by excellent aesthetics and extraordinary durability. With GFK Luxum®, thanks to its extraordinary properties, often exceeding Solid Surface, you can realize dreams of unusual, designer interiors, which are also characterized by individual character and excellent utility properties.

GFK Luxum® comes in several varieties, which differ in terms of physical and chemical properties and price. The highest quality GFK Luxum® material is used in the realization of sanitary products to the size of bathtubs, shower trays, washbasins, countertops and bathroom furniture, and wherever there is contact with drinking water and leather. GFK Luxum® is used to create products with unusual shapes. It is used not only for the implementation of various sanitary equipment projects, but also for unique architectural forms, large-size decorations and small architecture such as the GFK Luxum®:

sculptures

big balls and globes, domes

seats

playground elements

flowerpots

Buildings and enclosures

lamps with unusual shapes and forms www.luminato.eu

and even mini ski jumping hills

GFK Luxum® is the perfect choice

On request, GFK Luxum can contain a polymeric microban with silver nanoparticles with strong bactericidal and fungicidal properties. Thanks to this, sanitary products can be used for allergy sufferers and customers requiring microbiological purity.

Cristalstone

Cristalstone is a high quality, modern conglomerate developed by specialists. A material combining the characteristics of ceramics and sanitary composites. Cristalstone looks and feels like ceramics, but is more durable mechanically. Thanks to the properties of Cristalstone, wash basins, bathtubs, shower trays or bathroom countertops can have distinctive, modern forms, unattainable in the case of ordinary ceramics. It is also important that sanitary products from Cristalstone can be fitted to an unusual size.

Most often, hotel sinks and shower trays are ordered from Cristalstone, because in the case of “cast marble”, which is the Cristalstone conglomerate, a complicated casting form is required. Its cost is spread over the quantity of manufactured sanitary products. Hotel sinks and shower trays from Cristalstone are characterized by excellent aesthetics and high resistance to intensive conditions of use. It is also distinguished by a very favorable price when ordering at least a few pieces of the same product.

Unique Corten steel with high weather resistance

Cortene steel is a type of low alloy steel, on the surface of which under the influence of humidity from the air, a decorative rust patina is formed. Rust is formed on the sheet metal surface without interfering with the depth. In addition, the “rusted” Corten steel requires special treatment. Improperly prepared, it can corrode like ordinary steel. Initially it looks like a regular sheet metal, so it is often counterfeited and forged. The effects of this can be fatal. Therefore, it is very important to choose the right contractor. Korten steel comes in two varieties and is produced as sheet metal, only in two steelworks in Europe.

In Luxum, rusty Korten steel sheet is used to produce avant-garde, designer wall panels, facades and small architecture.

CARBON carbon fibre + resin

Carbon (carbon fiber reinforced plastic – cfrp) CFRP (Carbon Fiber Reinforced Plastic) is created by combining carbon fibres, i.e. reinforcement and epoxy resin, which is a binder. The most important feature of each type of carbon composite is its excellent mechanical properties at low weight. The composite has on average six times higher tensile strength and on average three times higher coefficient of elasticity than steel, with four times lower weight (average tensile strength 2.5 GPa, average coefficient of elasticity 450 GPa, density 1.75g/cm3). Carbon fibers have a low coefficient of thermal expansion and are characterized by high dimensional stability. Their favourable mechanical properties do not change even at high temperatures.

Why Carbon?

Carbon fibre is most often used to make not only composite tops, but also the most modern space vehicles, airplanes, rally cars (including F1 cars, Ferrari, Lamborghini), the world’s most expensive yachts and structures requiring extraordinary mechanical strength while maintaining low weight. Carbon fibre, popularly known as “Carbon”, is a very expensive but desirable composite, highly valued by many customers and world-class designers. For some time now, Carbon has been used to create exclusive goods such as furniture, bathtubs, washbasins, shower trays and architectural decorations. The furniture made of Carbon, with the visible, characteristic structure of this composite, breaks price records.

To sum up, state-of-the-art technologies and Luxum’s experience allow us to provide sanitary products, table tops and furniture made of Carbon and architectural creations made of this composite in perfect quality. What is more, Luxum delivers Carbon furniture on behalf of individual and institutional customers. Table tops, tables and benches made of various weaves of carbon fabric are the most popular. Institutional clients also order representative furniture and decors. The industrial branch of Luxum www.carbonc14.pl also manufactures Carbon tubes, conical tubes, plates, fittings, profiles, covers, casings, body parts and more.

KEVLAR aramid fibre

Aramids – a group of polymers, a kind of fibrous polyamides. Their characteristic feature is the presence of the main aromatic groups in their chains. Some aramids contain only aromatic groups between amide bonds, others also contain aliphatic groups. The more aromatic groups in its structure, the higher the mechanical, thermal and fire resistance, but also the lower the solubility, which results in increased processing difficulties. This is why it requires exceptional processing experience.

Kevlar is a material known for its unconventional strength properties. It is desired by connoisseurs of unusual materials. Aramid fibres are used to produce bulletproof vests, protective layers in clothing for firefighters, aviators, rally drivers and astronauts. Aramid rods are also used for the production of yacht masts, ski poles and other elements requiring high mechanical resistance. Finally, these polymers are used in the form of thin films – which are then pressed into other materials to create laminates with high mechanical resistance and elegant worktops.

Aramid was invented in 1965 by Stephanie Kwolek at DuPont. Luxum proposes the use of Kevlar in the production of ultra-light and durable architectural forms and specialized furniture. The industrial department of Luxum produces, among other things, various types of covers, casings, floor plates for rally cars, car body parts for cars and helicopters, details and fittings with unique physico-chemical properties.

HPL

HPL comes from the words high pressure laminates, i.e. high pressure laminate. It is a layered thermosetting plastic, created under conditions of high pressure of 7-9 MPa and temperature of about 150 degrees. It consists of several layers of paper impregnated with phenolic resin and decorative paper impregnated with melamine resin. It is possible to cover it with an additional layer protecting against weather conditions.

HPL laminate shall be demonstrated:

high impact resistance

high temperature resistance

resistance to bending and tearing

chemical resistance resistance resistance resistance to UV radiation

colourfastness

electrostatic properties

HPL laminates are successfully used both indoors and outdoors. For the furniture industry, laminates with a thickness of 0.5 to 1.5 mm are the most commonly used. HPL boards produced as a result of veneering are processed like hard wood or melamine board.

Outdoor use:

façade panels

roof soffits

balcony buildings

internal use

composite worktops

sills

partitions

door

bowling lanes

medical and other pool furniture

All materials marked with the HPL name must have appropriate properties and meet technical requirements strictly defined by PN and EN. Luxum provides the highest quality products using HPL.

NATURAL VENEERS

The essence of nature, the emphasised rings of the wood from which a given veneer is made, give the furniture a unique character of exclusivity. What is important is the quality of the veneer itself and the ability to position it. It is worth remembering, because natural veneer is a material requiring experienced carpenters.

LUXUM DELIVERS THE HIGHEST QUALITY VENEER FURNITURE!

Veneer is a thin sheet of wood obtained by cutting flat (tangential – in the direction perpendicular to the fibres) or peripheral (peeling). These sheets are 0.1 to 8.0 mm thick. Veneers are divided according to their use into veneers and cladding. Depending on the efficiency of the drawing (different tree species – different drawings), veneer can be used for plywood, veneer – veneering, or laminated wood – pressed. The veneer is used for round wood with large diameters. In addition, the preparation of the raw material for veneer includes: division of logs and logs into appropriate lengths and plasticisation of jumps.

Plasticisation is carried out by boiling the raw material in water or by evaporation with saturated steam. The plasticisation takes place more quickly during evaporation. As a general rule, 1,5-2 hours for each centimetre of radius of boiling water is used for steaming and 2-3 hours for cooking. Veneer drying to a moisture content of 15-18% is carried out by means of roller dryers or belt dryers. The veneer intended for veneers is placed in packets in the same order as the individual sheets are cut.

At Luxum we use veneers of Polish and American production with a minimum thickness of 0.55 mm, which is why we ensure the highest quality and durability of our veneered furniture.

MDF

Wood-based material produced by industrial method. High quality MDF used in Luxum company guarantees repeatability of shapes and maintenance of bending radii. The MDF used by us with different densities and elasticities, matched to the appropriate bending profiles, guarantees the possibility of deep milling without the risk of delamination or deformation after milling. Luxum specializes in professional protection of MDF boards against moisture absorption. We paint MDF in any colour, with the highest quality polyurethane, acrylic and ceramic varnishes. From piano gloss to matt. Modern, dust-free Luxum paint shop guarantees excellent paint quality.

High quality MDF is the basic material for the construction of custom furniture in Luxum, and in the industrial department for obtaining prototypes and models with the use of CNC milling in 5 axes. Particular attention is paid to products made of bent MDF and wall panels made of MDF 3D.

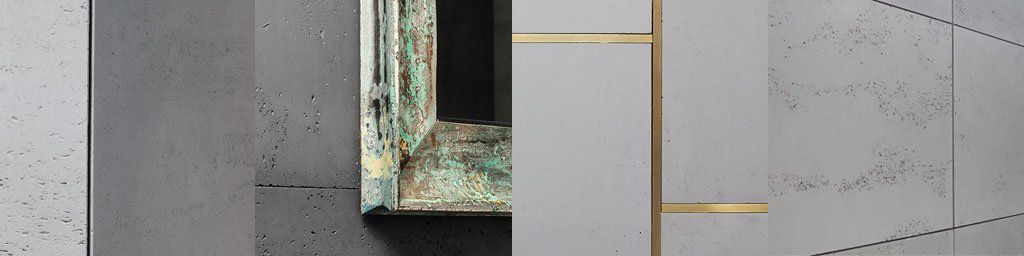

ARCHITECTURAL CONCRETE

Creative Concrete – the most modern architectural concrete on the Polish market, in the form of decorative panels for walls, facades, floors, fireplaces, fences, small architecture. Architectural concrete Creative Concrete in slabs is the first of its kind, real, natural concrete with no harmful fibers. The lack of artificial fibers in Luxum architectural concrete is due to the highest quality concrete with high strength and a unique method of production and maturing, unprecedented in Poland. Concrete mix and methods of production of Luxum architectural concrete make the panels relatively lightweight, very durable, pleasant to the touch, easy to process, cut, drill holes, with the possibility of quick installation on glue. Luxum Creative Concrete concrete slabs are available in a smooth version, but the most commonly chosen is a porous structure with deep pores (crampons), characteristic of Italian travertine. Architectural concrete Luxum is available in 8 colours and different sizes (also as large-size slabs).

Luxum guarantees a comprehensive customer service and delivers an order in guaranteed quality. Luxum also provides processing and delivery of elements where they can be used:

stainless steel

architectural concrete

polymer concrete

ultra-lightweight multilayer plates (honeycomb)

forged steel

aluminium

copper

toughened glass

Plastics – Plexiglas, ABS, PVC, HIPS and other types of plywood and many more…