ARCHITECTURAL CONCRETE

concrete slabs No 1 in Europe

beautiful interiors • luxury elevations

Architectural concrete Creative Concrete from Luxum is natural – without artificial fibres!

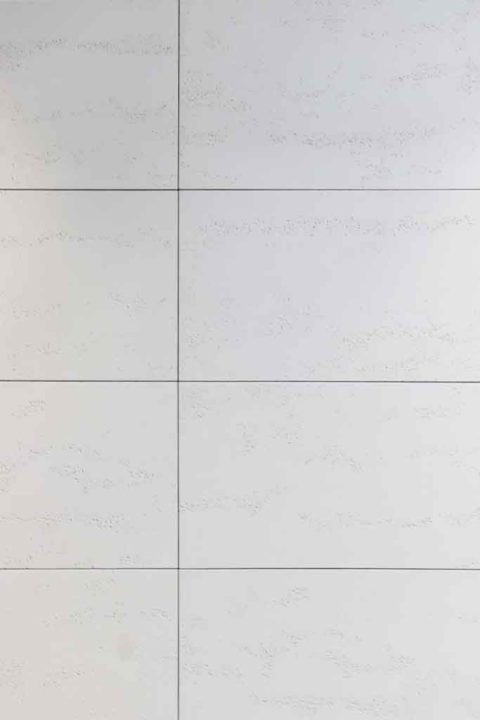

Concrete slabs for quick assembly with a perfect decorative effect of the most modern, real architectural concrete for walls, facades, fences, floors, terraces, stairs, fireplaces, countertops and small architecture.

Creative Concrete architectural concrete slabs created with love for beauty and respect for the environment.

Architectural concrete Luxum does not contain artificial glass or polypropylene fibres, which can be harmful to health, especially for children, asthmatics and allergy sufferers.

Application of

- floors

- interior walls

- exterior walls

- terraces

- facades

- plinths for fireplaces

- fences

- public buildings

Architectural concrete slabs are an optimal solution for perfect, ecological and economic investment in finishing walls, floors, facades, terraces and fences.

When ordering Creative Concrete concrete slabs, you also receive a guarantee of installation (paid) throughout the EU, by an authorized assembly team.

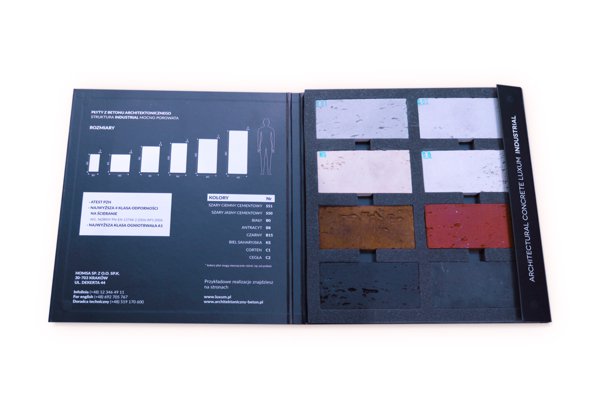

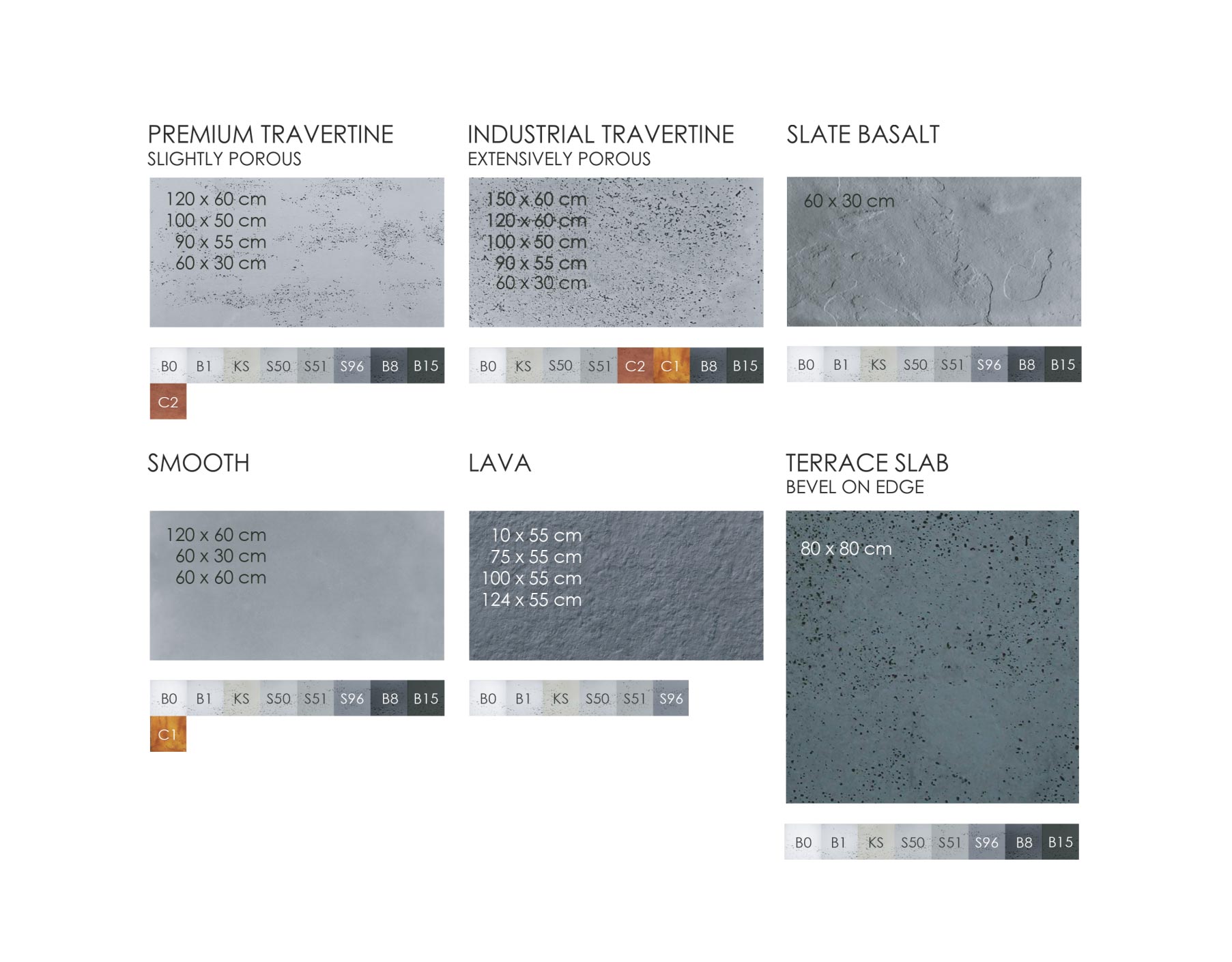

structures

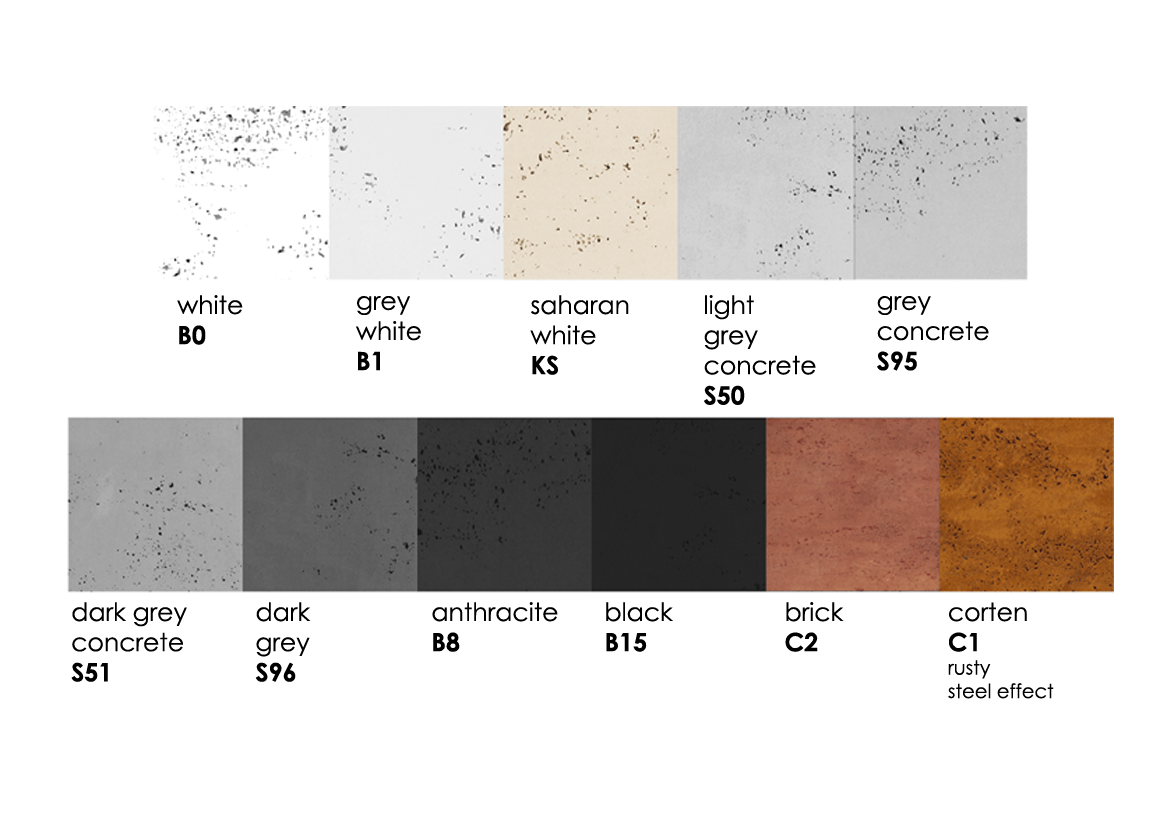

colors

12 SELECTED COLOURS TO CHOOSE FROM

PRICELIST

premium travertine

| sizes | price* |

|---|---|

| board 120 x 60 x 2 cm | 169 PLN per piece |

| board 120 x 60 x 3 cm | 206 PLN per piece |

| board 100 x 50 x 2 cm/1,5 cm | 119 PLN per piece |

| board 90 x 55 x 2 cm/1,5 cm | 115 PLN per piece |

| board 90 x 45 x 1,5 cm | 95 PLN per piece |

| board 60 x 30 x 2 cm/1 cm (is possibility to order tiles a schist texture) | 39 PLN per piece |

| board 60 x 60 x 2 cm | 95 PLN per piece |

| board 80 x 80 x 3 cm | 149 PLN per piece |

industrial

| sizes | price* |

|---|---|

| board 150 x 60 x 2 cm | 198 PLN per piece |

| board 120 x 60 x 2 cm | 169 PLN per piece |

| board 100 x 50 x 2 cm | 119 PLN per piece |

| board 90 x 55 x 2 cm | 115 PLN per piece |

| board 60 x 60 x 2 cm | 95 PLN per piece |

| board 60 x 30 x 2 cm | 39 PLN per piece |

lava

| sizes | price* |

|---|---|

| board 124 x 55 x 1,5 cm | 169 PLN per piece |

| board 100 x 55 x 1,5 cm | 119 PLN per piece |

| board 55 x 75 x 1,5 cm | 93,75 PLN per piece |

| board 10 x 55 x 1,5 cm | 9,16 PLN per piece |

tiles with a smooth texture

| sizes | price* |

|---|---|

| board 30 x 7 x 1,2 cm | 5,70 PLN per piece |

| board 40 x 8 x 1,4 cm | 8,70 PLN per piece |

floor tiles a premium texture

| sizes | price* |

|---|---|

| board 120 x 60 x 2 cm | 195 PLN per piece |

| board 120 x 60 x 3 cm | 206 PLN per piece |

| board 100 x 50 x 3 cm | 138 PLN per piece |

| board 150 x 60 x 3 cm smooth plate | 228 PLN per piece |

| board 60 x 60 x 2 cm | 110 PLN per piece |

| board 80 x 80 x 3 cm | 149 PLN per piece |

*Prices do not apply to plates in colours BS, B15 - extra charge 25%, colours B8, C2 - extra charge 15%, colours C1 - extra charge 40%

Adhesive for mounting concrete slabs – MS nanotechnology adhesive

Extremely durable, fast in application professional adhesive for fixing concrete slabs in interiors and on facades. Dedicated to concrete slabs and natural stone, with a formula safe for health and the environment. One-component adhesive Luxum is extremely simple in application, thanks to a specially developed, slim tip for precise glue application.

Hydrophobic impregnate to protect concrete surfaces

Impregnation for architectural concrete Luxum protects the slabs inside and outside buildings, and at the same time is a completely safe product that allows the slabs to breathe. Thanks to this, it significantly eliminates the phenomenon of settling dust and makes it easier to keep the concrete surface clean. It can be applied by spraying or roller. It dries quickly, does not stain concrete surfaces, and what is important – it is 100% matte.

Hybrid primer for assembly of architectural concrete

Hybrid Surface Contact Contact IPX-8 is the most modern primer on the Polish market with an innovative recipe and comprehensive, universal properties. It has been developed and manufactured especially for Luxum®, intended for the assembly of architectural concrete in the form of decorative slabs for interior walls and for facades. This is the only specialized hybrid primer that is easy to apply, dries quickly and combines the advantages of penetrating, reinforcing and bonding primer with the waterproofing function.

Creative Concrete concrete slabs have unique advantages:

Architectural Concrete – Concrete from Luxum® is safe for the natural environment, free of VOC, does not emit unpleasant odors. No dust and no fading. It is friendly for people with allergies, children, animals and the environment.

PZH certificate confirms health safety of architectural concrete with the possibility of using both private and commercial buildings outside and inside the premises.

CE certificate for architectural concrete, confirms the adjustment of quality to the requirements of European certification and the possibility of using decorative slabs in rooms and on facades, as well as fences for public buildings and private homes.

Modern concrete architectural concrete is a durable and timeless cladding material. What’s more, the lack of efflorescence and corrosion of the concrete makes the minimum durability shelf life is 80 years.

- 100% safe

- highest efficiency

- created with care for the environment

ARCHITECTURAL CONCRETE ASSEMBLY:

Check and order the available samples of architectural concrete in two unique structures: medium and highly porous. Architectural concrete slabs from Luxum are available in many colours and sizes.

DELIVERY GUARANTEES

In order to provide the best possible service, Luxum guarantees a safe delivery and, in the event of a rare transport damage, a follow-up delivery is arranged immediately after an application has been made together with the damage report. Without waiting for transport compensation.

Services are offered throughout Poland, including cities such as Warsaw, Krakow, Wroclaw, Poznan, Gdansk, Lodz, Bydgoszcz, Szczecin, Gliwice, Białystok, Kielce and Lublin.

Luxum is one of the few manufacturers of architectural concrete that has a continuous production and inventory. Therefore, an order for architectural concrete is usually completed within 48-72 hours, and in the Małopolska region even within 1 day. Orders can also be picked up personally from the warehouse at the showroom, and large investment or supplementary orders can also be picked up directly from the production plant.

For concrete slabs, Creative Concrete Luxum provides full technical advice with a special consumer hotline, which is open longer than the company’s office and living room. So that you can benefit from professional advice at every stage. Both before placing an order and during the preparation for assembly.

Architectural concrete Creative Concrete – definitely a good choice.

INFORMATION

material

opportunities

Why architectural concrete Creative Concrete?

Excellent aesthetics and the easiest assembly among all concrete slabs on the market. Creative Concrete architectural concrete is a prefabricated decorative slab in various sizes, with the best quality parameters and aesthetic qualifications. The manufacturer of concrete slabs Creative Concrete is number 1 in Poland, as one of the few on the market offers architectural concrete fully natural, without the content of artificial fibres.

Architectural concrete works well as a decoration both indoors and outdoors. Creative Concrete concrete slabs have a universal character. Thanks to this, they can be an elegant decoration in both industrial, minimalist, modern and classic interiors, but also blend perfectly with antiques and interiors of eclectic and glamorous character. It is interesting to note that it is definitely the best place to relax and rest in cool colours. Architectural concrete is therefore an ideal, natural material for people who want to relax in a friendly environment. It is important to choose the right proportions, especially if the interiors are to be warm in reception. Architectural concrete blends well with wood, glass, brass, stainless steel, Corten and Solid Surface composites in monolithic colours and carbon fibre.

| sizes | textures |

|---|---|

| 120 x 60 x 2 cm 120 x 60 x 3 cm 100 x 50 x 2/1,5 cm 90 x 55 x 2/1,5 cm 90 x 45 x 1,5 cm 60 x 30 x 2/1 cm 60 x 60 x 2 cm |

premium texture |

| 150 x 60 x 2 cm 120 x 60 x 2 cm 100 x 50 x 2 cm 90 x 55 x 2 cm 60 x 30 x 2 cm 60 x 60 x 2 cm |

industrial texture |

| 30 x 7 x 1,2 cm | floor panel a smooth texture |

| 40 x 8 x 1,4 cm | floor panel a smooth texture |

| 60 x 60 x 2 cm | panel a smooth texture |

| 80 x 80 x 3 cm | premium texture/pavement plate, terrace |

| 55 x 10 cm 55 x 75 cm 100 x 55 cm 124 x 55 cm |

lava |

The architectural concrete formula of Luxum Creative Concrete has been designed to eliminate operational and installation problems.

Anyone with experience in the installation of ordinary ceramic tiles or decorative stone can handle the installation of Creative Concrete tiles.

Together with the boards, you can also order a professional architectural concrete adhesive with a strength of 22 kg per 1 cm. There’s no mistake! Creative Concrete, a hybrid concrete adhesive for architectural concrete, is produced by a Dutch company for a special order and is unrivalled in terms of strength and flexibility.

In addition, the offer includes a specialist ground to strengthen walls and a perfect impregnate, created especially for architectural concrete. Creates a waterproof barrier and protects against dirt.

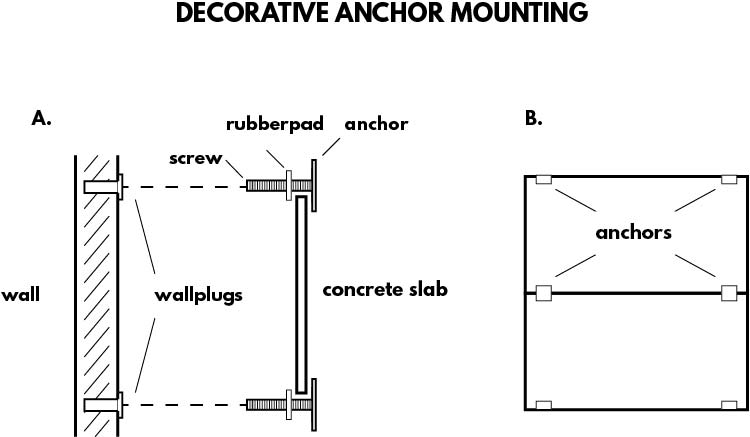

Creative Concrete concrete slabs can not only be glued together, but also anchored to standard stone anchors that are not visible (without the need for expensive specialist systems) or decorative anchors that are visible between expansion joints.

The plates can also be screwed onto the screws. For those who opted for industrial-style screw mounting, Luxum offers two types of decorative screw head caps to make the installation complete and aesthetically pleasing.

Transports are carried out at Luxum’s own risk, by company transport or courier.

CREATIVE CONCRETE CAN ALSO BE ANCHORED AND SCREWED IN.

Check how the installation looks like

CREATIVE CONCRETE ARCHITECTURAL CONCRETE IS NATURAL

Creative Concrete architectural concrete does not contain artificial glass or polypropylene fibres that can be harmful to health, especially in the case of children, asthmatics and allergy sufferers.

CREATIVE CONCRETE ARCHITECTONIC CONCRETE SLABS POSSESS A CE-CERTIFICATE marking placed on the product as a declaration of the manufacturer that the marked product meets the requirements of the European Union directives.

Research on the properties of ARCHITECTONIC concrete from LUXUM

laboratory tests confirm the best parameters of concrete offered by Creative Concrete. The results objectively show that the parameters of the concrete slabs from Creative Concrete are comparable or superior to those obtained for ceramics and natural stones and all competing architectural concrete slabs. Architectural concrete proposed by Creative Concrete combines the technical parameters of ceramics, natural stone and concrete, which allows to achieve a unique, perfect effect.

Creative Concrete concrete slabs from the standard offer do not contain artificial fibres, so they do not dust, do not turn yellow, are easy to process and install.

Unique architectural concrete technology, thanks to which we achieve a quality and aesthetic advantage, so that the result of architectural concrete is perfect every time.

perfect, natural aesthetics

highest mechanical strength

highest water resistance

lowest weight

Creative Concrete architectural concrete slabs

fire resistant and frost resistant

Creative Concrete is non-flammable –has the highest class of fire resistance A1

has the frost resistance of up to -40 degrees Celsius.

moisture resistant

Creative Concrete’s “live” architectural concrete slabs, unlike GRC artificial concrete slabs and other imitations, are real, “breathable” concrete slabs impregnated with Luxum impregnates, concrete slabs can be used in the toughest wet conditions.

abrasion resistant

Creative Concreteconcretepanels have the highest abrasion resistance class IV for concrete – DO NOT DUST – therefore they are also willingly used on floors.

Compressive and crushing strength

HOW TO ORDER

How to order architectural concrete?

Send us an e-mail or send us a contact form: a project with a description of your needs, delivery address and contact phone number.

If you do not have a project, please specify: type of concrete slabs, surface structure (premium travertine, industrial, smooth slab), colour of slabs, their number and size.

If you plan to install the adhesive – specify the type of surface and the amount of surface to be installed, expressed in m2, it will allow the advisor to determine the amount of adhesive needed, possibly additional primer to the substrate and the reverse side of the board and the impregnate.

Delivery time and transport

At Luxum we perfectly understand that finishing works should be carried out smoothly and without any problems. Time in this case is not only money, but also doubts about the timely completion of the investment. We know that you can worry about the timing and quality of your delivery. We have done our best to make sure that the concrete slabs you order reach their destination quickly and without stressful problems.

Where are your concrete slabs now?

– They are waiting for the formalities to be completed.

Your concrete slabs and all installation accessories are probably already manufactured. Architectural concrete Luxum, matures in comfortable conditions, in a strictly controlled atmosphere. Computer controlled temperature and humidity control makes the boards prepared for you much more durable and beautiful than other boards available on the market. They don’t have any weird spots or blooms. They will not crack when cutting or drilling holes.

How are the boards prepared for transport?

– safely and securely packed.

When the order is received, the boards are once again inspected and prepared on pallets for transport. The boards are laid horizontally and interlaced with soft foamed polystyrene boards. Corners are protected and the whole is wrapped with thick foil and fastened with transport belts. Horizontal packing guarantees that after unlocking the pallet, the boards will not tip over and will not hurt anyone. On the pallets there are placed consignment notes and instructions to be followed by the forwarder and the recipient. We have been doing this for years and it is the best, proven solution. And we’ve already made thousands of deliveries.

How will I receive my delivery?

– quickly and according to your placed order.

The Luxum architectural concrete slabs are delivered throughout Poland and Europe by leading transport companies. The insured transports are carried out by trucks with an unloading ramp. The slabs will arrive wherever technically possible and comply with the regulations. The driver is equipped with a pallet truck and will help with unloading. You can always make an appointment for a personal pick-up. Large, wholesale quantities are delivered by dedicated transport on individually agreed terms.

Who’s in charge of transport? – Luxum. You don’t have to worry about anything.

Your concrete slabs are in responsible hands and we believe that they will reach you quickly and without any damage. Although Luxum architectural concrete slabs are extremely durable, it is possible that occasional damage can occur during loading and unloading. After receiving a properly completed damage report and sending the photos, new copies are sent immediately at Luxum’s expense.

Luxum assists in the selection, transport and installation of architectural concrete slabs throughout the EU.

Delivery usually within 48 hours*

Panels – Luxum concrete slabs are characterized by high quality thanks to which the final decorative effect is perfect. Additional comfort is brought by the awareness that the architectural concrete used in the device meets all the norms, is safe and will be able to fully enjoy the modern architectural solutions even for decades. It should be remembered that concrete has been shaping trends in architecture and decoration since the 1920s. In Poland, a specific fashion for architectural concrete has been going on for only a few years and everything points to the fact that it is only the beginning of this trend. The original, inaccessible austerity of the concrete has been tamed in Luxum architectural concrete slabs. Luxum concrete panels are smooth, pleasant to the touch, devoid of roughness and at the same time porous, with deep crampons that give a unique, modern character.

*depending on the size of the order

Simple and safe!

At Luxum we took care of the comfort of placing enquiries and orders

Find out how, when and for how much you will receive your order.

Send by e-mail, post, present your idea, design, drawing, sketch, photo, description with approximate dimensions, colours, shapes, etc. to our office or to the Luxum

mobile consultant.

If you are interested in sanitary equipment, furniture, small architecture, composite products, worktops, interior design, architectural concrete – send us an e-mail or contact us using the contact form.

If you are inspired by any of the presentations on the LUXUM website, please provide in your correspondence the number of the photo from the gallery.

After accepting the application, we will contact you in order to advise on the most advantageous solutions, make a valuation of the investment, discuss the terms and conditions and accept the order. We are always available via phone.

FILL THE FORM

FREE VALUATION

Additional information

Please state the place of delivery and contact phone number in your correspondence, it will significantly facilitate the correspondence and precisely calculate the price of delivery.

All prices on the website are gross prices and include all taxes.

In the case of ordering parties who are also consumers, the prices that are given in the correspondence are always gross prices. In the case of entrepreneurs, the commercial offer may be issued in the net price.

All guarantees provided by LUXUM do not limit the rights of consumers due to non-compliance with the contract.

Consumers of LUXUM company have the right to return the purchased goods within 14 days, unless the products are prepared for the individual order of the consumer. Returned goods should be complete, not bear traces of use and have the original packaging.

All orders are covered by a third party insurance policy, which is guaranteed by ALLIANZ with a sum insured of PLN 1,000,000.

The liquidity of the transaction is supervised by BIG INFOMONTOR.

Privacy information

At LUXUM we respect the privacy of our customers. All contact details provided to us shall be used exclusively for the purpose of processing orders. We will not pass on your data to third parties unless it is required for the proper execution of your order. For more information see the “Privacy Policy”. Be sure to read the Regulations available below.

*MOBILE LUXUM ADVISORS.

travel to the place indicated throughout the EU and associated countries. They have the necessary knowledge and qualifications in the field of construction, renovation and adaptation of interiors. Mobile consultants are equipped with the necessary equipment to perform a professional measurement. They also carry material samples with them. Ordering consultation with MOBILE LUXUM ADVISORS may be associated with a fee. The fee for the advisor’s visit is set and stated in full, before arrival.

INSTALLATION AND DOCUMENTATION

to download

assembly

Architectural concrete slabs Creative Concrete

have been designed and manufactured so that they can be easily, quickly and economically installed. The innovative composition of the mix and special production conditions on the Polish market of architectural concrete make Creative Concrete Luxum so good and can be effectively, quickly and relatively cheaply installed, without the need for specialist solutions and a specially trained team. Thanks to Luxum solutions you save time and money.

It is also worth taking into account the fact that the concrete slabs from Luxum can be delivered to the construction site in Poland within 24 hours.

Creative Concrete concrete slabs are cut and machined like large ceramic tiles, and in the vast majority of cases are glued together.

Before installation, always read and observe the information and recommendations contained in the regulations and pass them on to the installer.

ASSEMBLY INSTRUCTION

We also recommend Luxum’s authorized assembly teams, whose experience and knowledge in the assembly of concrete slabs will allow for flawless assembly.

Mount the plates evenly and keep them level. Use a spirit level and do not level the plate to the plate.

The final effect must be taken into account, not the episode. When the slab does not adhere to the slab according to the level, it can be properly ground. This is not a problem because they are concrete slabs. In addition, the edges should be wiped away from any dust and possible unevenness.

Luxum offers 2 types of adhesive for architectural concrete. Ask your consultant which adhesive is right for your planned installation.

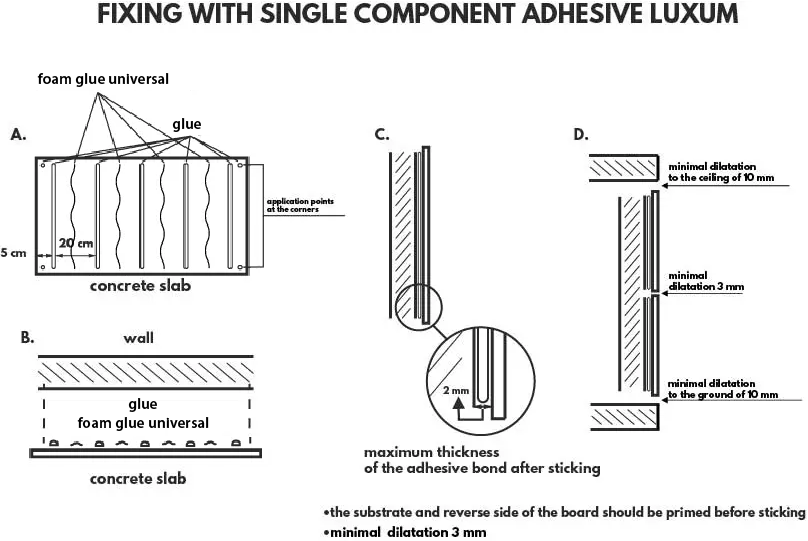

Concrete slabs Luxum single-component adhesive mounting

Hybrid glue, waterless Invisible

installation method

290 ml cartridge – yield up to 1.5 m².

Decorative concrete slabs can be glued to:

Internal walls,

facades,

floors,

fences,

small architecture,

terraces.

Creative Concrete architectural concrete slabs can be glued with one-component adhesive up to a board thickness of 2 cm and a size of 120×60 cm, and the facade up to a size of 100×50 cm.

The maximum weight of the material to be fixed per square metre must not exceed 35 kg.

Remove oils, fats, dust and poorly bound paint or varnish coatings, as well as residues from previous adhesives, paints, etc. from the substrate.

In case of connections with highly porous and absorbent substrates, e.g. gas concrete, it is recommended to use a primer for hybrid adhesives. If in doubt, carry out an adhesion test.

The substrate should be load-bearing, seasoned, free from coats, weak plasters, paint coatings and wallpapers.

In the case of weaker substrates and gypsum plasters, it is recommended to align the walls with GK or unpainted OSB.

Stick concrete and stone slabs to the substrate within max. 8 minutes.

Determine the size of the joint with crosses and press evenly against the plate to be installed. For optimal durability, press the boards with the glue applied to the substrate so that a 2-3 mm ventilation gap is created between them. The spacing will ensure that the adhesive joint is able to transmit deformations well.

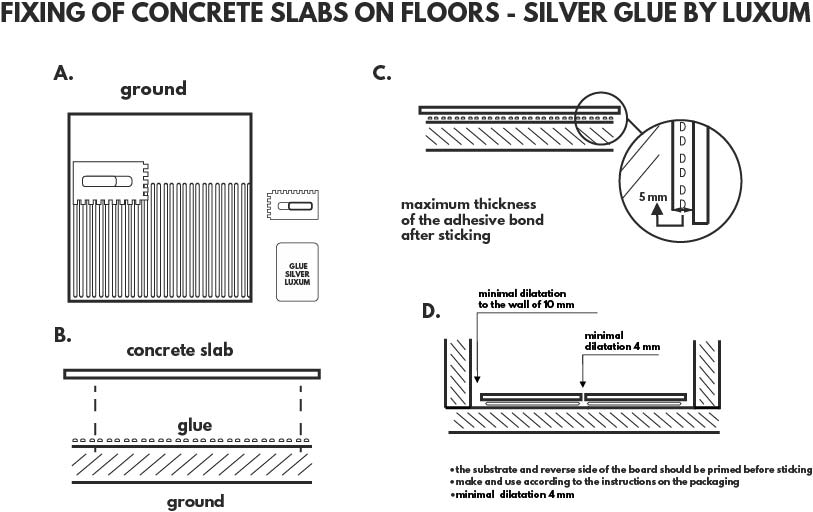

Fixing of concrete slabs on floors – silver glue by Luxum and glue Sika Bond-T8

Invisible installation method

Before installation, impregnate the concrete slabs with Luxum architectural concrete impregnate twice using the “wet on wet” method, evenly with a sponge roller or with a short bristle. Impregnate the front and sides of the board, as well as the cut areas.

25 kg bag – up to 5 m² capacity

Apply the reverse side of the concrete slab and the substrate with quartz sand primer, concrete-contact type, apply the adhesive with a trowel and trowel over the entire surface in accordance with the instructions of the Luxum adhesive manufacturer.

Determine the size of the joint with crosses and press evenly against the plate to be installed. In the case of large format boards, you can use levelling strips, e.g. Rubi System.

Luxum offers two types of glue for architectural concrete. Ask your consultant which adhesive is right for your planned installation.

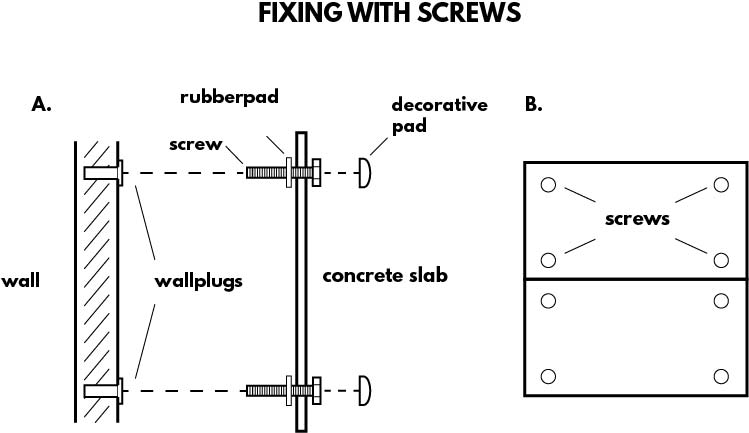

Fixing the concrete slabs with screws

Fixing the concrete slabs with screws

Visible, decorative way of installation

Mounting the boards on screws is a very simple, effective way of mounting with an elegant decorative effect. The screws allow to mount Luxum concrete slabs in any size and thickness.

Impregnate the Creative Concrete concrete slab byLuxum before installation or cutting.

Drill holes in the corners with concrete drills without impact.

Attach the plate to the ground and mark with a pencil the places where dowel holes are drilled. Drill holes for the expansion plugs in the substrate. Attach and fit the tiles to the ground. Tighten with screws without applying too much pressure to the floor. A flexible pad should be used on each side of the plate. Place the decorative stainless steel caps from the Luxum range on the screw heads.

Anchor mounting of concrete slabs

Invisible installation method, ventilated facades

Creative Concrete architectural concrete slabs can be anchored to standard, generally available stone anchors. This method of installation of concrete slabs is particularly recommended for the installation of large-size slabs 120×60 cm and larger with a thickness of 3 cm.

Anchoring is most often used for the assembly of concrete slabs on high façades and ventilated facades with insulation with a thickness of more than 15 cm.

Impregnate the concrete slab before installation or cutting.

Measure and drill holes in the façade and side of the concrete slabs.

Place the anchors in the mounting holes, secure with mortar and anchor to the ground. For complex facades, use stabiliser plates to fit in. Use only certified anchors.

It is also possible to mount it on visible decorative anchors with caps – interiors and facades.

Installation of concrete slabs for OSB and GK slabs

Creative Concrete architectural concrete in cladding is characterized by excellent quality, durability and strength, but this is not a guarantee that it will not be damaged during or after installation. Therefore, the installation of architectural concrete slabs must be preceded by a thorough analysis of the substrate on which the cladding will be glued.

The substrate should be sound and stable, compact, seasoned and clean

You cannot install concrete panels on weak or gypsum plasters. If a gypsum plaster is to be used as a substrate, it should be chiselled, the surface should be levelled with cement-lime mortar or a substitute substrate made of appropriate GK or OSB boards should be installed.

OSB chipboards or plasterboard are relatively cheap and easy to process and install. When bonding architectural concrete slabs to them, certain rules must be observed and appropriate products must be used.

OSB board

It is a wood-based material made of coarse-graded chips, pressed onto sheets under pressure at high temperatures. The binder is a suitable resin, which reduces the adhesion of the adhesive. OSB, due to technical properties and conditions of use, are divided into classes:

OSB 1 – universal board, does not transfer loads, can be used inside the building, in dry and airy rooms. Not suitable for use as a base for architectural concrete.

OSB 2 – board capable of carrying a load. Use only in dry and ventilated rooms.

OSB 3 – load-bearing board, for installation inside and outside the building, in sheltered places, not exposed directly to moisture.

OSB 4 – a board with high parameters, carries high loads. Can be used under more difficult conditions, even in humid areas.

When installing Luxum architectural concrete slabs, OSB 3 and OSB 4 are used. They are successfully used as a substitute substrate.

OSB are easy to install, but can be a difficult substrate. Sometimes they twist due to factors such as humidity, excessive load, incorrect installation, etc.

Appropriate impregnation protects OSB and significantly extends its lifespan.

Architectural concrete wallcoverings on OSB can only be glued by a qualified professional. Starting with the lining, thoroughly clean the OSB from the layers that weaken the adhesion of the adhesive:

dust

fat

residues paints, varnishes.

The cleaned OSB should be wiped thoroughly (sanded) with abrasive paper and a primer should be used to increase the adhesion capacity. After the primer has dried, we start gluing concrete formats. The high formability of OSB boards limits the use of cement-based adhesives, except for high-plastic adhesives. The two-component adhesive for architectural concrete Luxum is a good choice here. It is characterized by high flexibility and excellent adhesion. The Luxum two-component concrete adhesive is white and does not cause discolouration when installing concrete slabs. It is important that both the substrate and the reverse side of the slab, i.e. the contact point between the concrete slab and the adhesive, is primed.

When OSB is installed in bathrooms – it is necessary to apply a high quality elastic foil to the subfloor. Flexible foil is best applied with a roller or brush, but not earlier than 8 hours after the application of the ground. The foil will protect the substrate watertight. It is best to apply the film twice in accordance with the manufacturer’s instructions. The second coat should be applied after the first one is completely dry, i.e. after about 3 hours. In expansion joints of walls and floors use sealing tapes – they should be glued into the fresh, second layer of elastic foil. After 24 hours, the installation of concrete slabs can be carried out in accordance with the procedures.

MFP board

MFP boards, like OSB, belong to the family of wood-based boards and consist of wood chips, compressed and bonded with resins. They differ from OSB by the chip arrangement – in the MFP building board the chips are arranged in different directions in the entire cross-section of the board, which makes its bending strength equal along both axes.

Currently, instead of OSB 3 we recommend MFP building board, which has much better technical parameters and is easier to process.

Plasterboard As the name suggests, plasterboards are made of altered stucco gypsum, where a weak plasterboard is glued to both sides of the board. GK boards are produced by type:

GKB (standard – ordinary) – general purpose boards, used as dry plasters for walls and ceilings. It can be used in rooms where relative humidity does not exceed 70%.

GKBI boards (impregnated) – such a board is produced as GKB with additional gypsum hydrophobic protection, where the addition of silicates is used. Panels for use in rooms with humidity not exceeding 85% – provided that the surfaces are completely covered with materials resistant to moisture and only in ventilated rooms. After reinforced installation of the slab and proper preparation, it can be used as a base for architectural concrete cladding.

GKF (flame-retardant) – gypsum cardboard boards with fibreglass admixture. Their characteristic feature is increased fire resistance. They are often used as a protection against fire and in the construction of cold fireplaces. We use them in rooms where the humidity is below 70%. After a solid, reinforced installation, they are suitable for the Creative Concrete architectural concrete cladding from Luxum.

GKFI (flame retardant, impregnated) – a board containing glass fibre and hydrophobic substance (water repellent). The board has a significantly increased fire resistance and is used in rooms where moisture can occur – such as bathrooms and attics. In bathrooms, use with flexible foil. GKFI enjoys excellent opinions from experts. This type of plasterboard can be used after proper preparation as a substrate for architectural concrete slabs.

GKP (base board for plaster) – the board most often installed on the supporting structure of buildings. It is a type of GK board with a high cardboard absorptive capacity – which is a great base for plaster. Not recommended for installation of concrete slabs.

Composite slab – slabs manufactured with the addition of an insulating material such as polystyrene or polyurethane foam. It can be used in interior insulation with insulation thicknesses from 20 to 60 mm.

In order to prepare the ground for the lining of architectural concrete panels made of plasterboard, we prepare the surface similarly to OSB, but we do not grind it.

As in the case of OSB, carry out a joint inspection at the point of contact between the boards. Fill the visible gaps with filler mortar. No thickening may remain on the surface of the GK boards.

Wet-zone installation

Bathrooms, spa, garages, kitchens, swimming pools etc. They’re damp rooms. We use green GK boards.

Please note that the green GK board is more resistant to high humidity in the air and will not degrade in direct contact with water. In a “wet” room, it is necessary to protect the substrate by applying double layers of elastic foil (liquid foil). In this way you will protect the green GK board from the destructive penetration of moisture, water and water vapour. Secure corners with a sealing tape, because the foil alone cannot withstand the stresses that are created in such a place. On the prepared surface it is possible to start gluing prepared, primed and impregnated concrete slabs. Glue with a high-elastic adhesive, ensuring high adhesion of concrete slabs, made of Luxum concrete to the surface.

When finishing with architectural concrete panels, e.g. bathtubs or plasterboard walls:

Apply a minimum of double layer of GK panels and significantly thicken the number of profiles used.

It is best to use reinforced door profiles instead of standard profiles for plasterboards. The substrate will then show greater stability.

OSB boards are more rigid and stable than GK boards. The thickness of OSB must not be lower than 22 mm, and in the case of OSB walls, a much thicker board and solid profiles must be used.

It is important to remember that GK and OSB, which are the base for concrete slab linings, absolutely must be installed professionally, which means solid and stable. The surface of the panels must be thoroughly cleaned. If the substrate is not prepared professionally, even the best adhesives can be used, which is the two-component adhesive for architectural concrete Luxum, which has the best opinions – it may not be completely satisfactory.

We encourage you to use the suggestions of authorized assembly teams during the assembly process.

*All installation instructions are for information only. More detailed information can be found in the regulations. The final decision on how and how the assembly should be carried out is made by the assembler or site manager.

ARRANGEMENTS

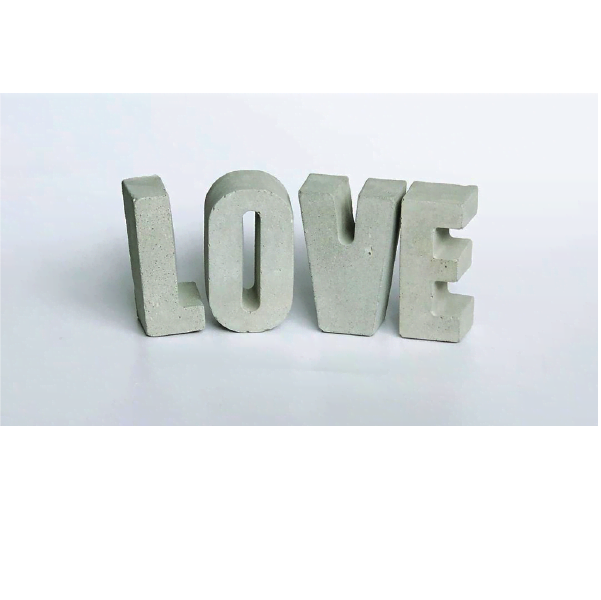

3D LETTERS form architectural concrete

Architectural concrete is currently one of the most desirable materials on the interior decoration market. It is available not only in the form of boards intended to cover walls, fireplaces, floors and facades, but also in the form of unique, personalized additions and decorations.

3D letters from architectural concrete are a great idea for an original gift – you can compose any inscription using the unlimited possibilities of the material, which is decorative concrete.

Decorative elements (3D letters) of architectural concrete are usually arranged as :

– inscription LOVE;

– inscription HOME;

– initials;

– child’s name;

– numbering of house fronts;

Concrete decorative letters can also be installed in outdoor conditions, as house numbering or other decorative elements.

Decorative concrete elements perfectly fit in with other fashionable materials: glass, wood, metal, brick and elements in white and black. What is more, they will also emphasize the space arrangements in the style of: glamour, Scandinavian, classic, industrial and lofty.

How to order letters from architectural concrete?

– choose letters, digits, special characters or symbols

– choose letter size;

– choose a font;

– choose a color;

– choose a texture (smooth, porous)

– choose the purpose of the concrete components (wall mounting, facade mounting, freestanding letters)

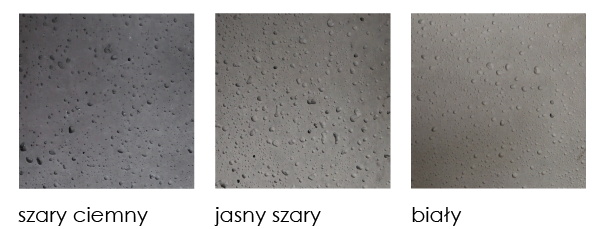

Colours of 3D letters from architecture concrete

Concrete accessories are 100% handmade from the best quality ecological raw materials of Polish origin.

On request, we can also supply letters with a stabilizing base or bars prepared for the assembly of concrete elements.

Architectural concrete letters are available in 3 selected natural grey colours.

Weight of one letter – from 0.5 to 1.5 kg – depending on the size selected

Thickness of the letters: 3 cm

Minimum height of one letter: 16 cm